In recent years, there has been a growing interest in sustainable building materials that offer both durability and aesthetic appeal.

One such innovation that has gained significant attention is WPC (Wood-Plastic Composite) wall panels.

WPC wall panels are a versatile and eco-friendly alternative to traditional wall cladding materials.

This essay explores the evolution of WPC wall panels, from their conceptualization to their current reality in the construction industry.

It examines the development of WPC technology, the advantages they offer, their applications, and the future potential of this groundbreaking material.

I. The Birth of WPC Technology

The concept of WPC wall panels emerged as a response to the environmental concerns associated with traditional building materials.

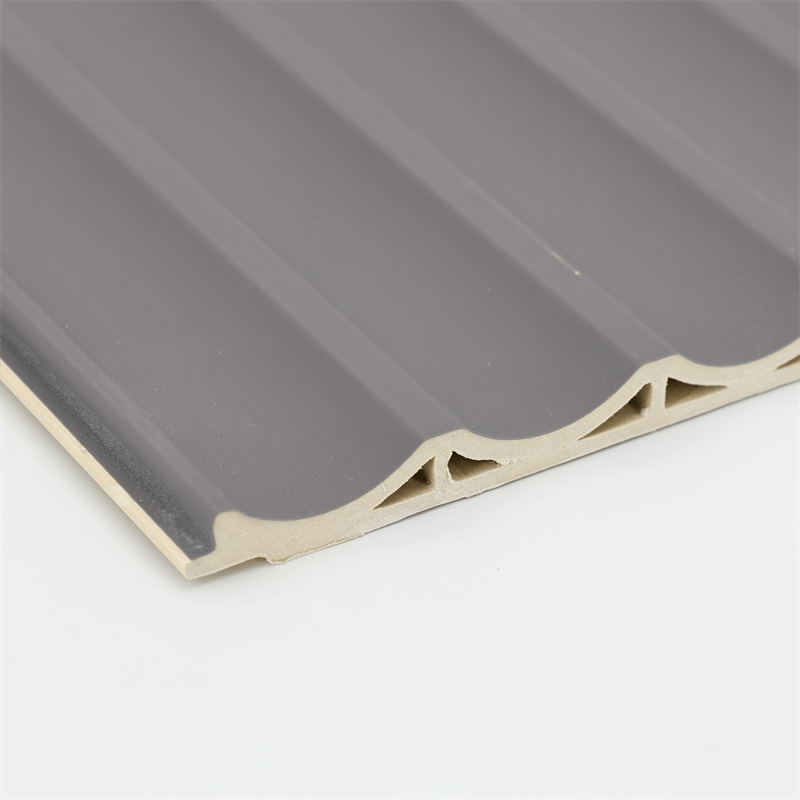

Developed in the 1990s, WPC technology combined wood fibers or flour with thermoplastics to create a composite material that possessed the advantages of both wood and plastic.

This fusion resulted in a product that showcased the natural beauty of wood while harnessing the durability, moisture resistance, and low maintenance properties of plastic.

II. Advantages of WPC Wall Panels

WPC wall panels have gained popularity due to the numerous advantages they offer over traditional wall cladding materials. First and foremost, they are highly sustainable.

By utilizing recycled wood fibers and plastic, WPC wall panels help reduce deforestation and waste.

Furthermore, their manufacturing process requires less energy compared to the production of other materials like concrete or steel.

Secondly, WPC wall panels are known for their durability. The combination of wood fibers and plastic creates a material that is resistant to rot, decay, and insect infestation.

Unlike traditional wood panels, WPC panels do not warp, crack, or splinter, making them an ideal choice for exterior applications.

Additionally, WPC wall panels require minimal maintenance. They do not require painting, staining, or sealing like natural wood panels.

A simple cleaning routine of occasional washing is enough to maintain their appearance, making them a cost-effective solution in the long run.

III. Applications of WPC Wall Panels

WPC wall panels find applications in a wide range of construction projects. In residential buildings, they are used for both interior and exterior walls, adding a touch of elegance and warmth.

The variety of finishes and colors available in WPC panels allows for endless design possibilities, making them a popular choice among architects and interior designers.

In commercial spaces, WPC wall panels are widely utilized due to their durability and aesthetic appeal.

They can withstand heavy foot traffic and resist moisture, making them suitable for high-traffic areas such as restaurants, hotels, and retail stores.

Moreover, WPC panels contribute to sound insulation, enhancing the acoustic quality of spaces.

IV. The Future of WPC Wall Panels

As technology continues to advance, the future of WPC wall panels holds great potential.

Research and development efforts are focused on improving the manufacturing process, exploring new composite materials, and enhancing the fire resistance properties of WPC panels.

The incorporation of nanotechnology and other innovations may lead to further advancements in the strength and performance of these panels.

Furthermore, with a growing emphasis on sustainable construction practices, the demand for WPC wall panels is expected to increase.

As regulations and building codes evolve to promote eco-friendly solutions, WPC panels are likely to become a standard choice in the construction industry.

The evolution of WPC wall panels has been a remarkable journey from concept to reality.

These innovative materials have revolutionized the construction industry by offering a sustainable, durable, and visually appealing alternative to traditional wall cladding materials.

With their numerous advantages and versatile applications, WPC wall panels have gained recognition among architects, designers, and builders.

As technology continues to advance and the demand for sustainable building materials rises, it is evident that the future of WPC wall panels is promising.

This evolution highlights the continuous pursuit of creating environmentally friendly and aesthetically pleasing solutions in the field of construction.

Cleverly combining the natural beauty of wood with the durability and low maintenance properties of plastic, WPC wall panels have proven to be a game-changer in the construction industry.

The journey from concept to reality has not only showcased the ingenuity of engineers and scientists but also emphasized the industry’s commitment to sustainable practices.

The advantages offered by WPC wall panels, such as their sustainability, durability, and minimal maintenance requirements, make them a compelling choice for both residential and commercial projects.

Their versatility in design, along with their resistance to rot, decay, and insect infestation, ensures that they will continue to be a sought-after option in the years to come.

Looking ahead, ongoing research and development efforts will likely lead to even greater advancements in WPC technology.

With a focus on enhancing fire resistance properties, exploring new composite materials, and incorporating emerging technologies, the future holds immense potential for WPC wall panels.

As sustainable construction practices gain momentum, WPC panels are poised to become a standard choice in the industry, contributing to the creation of greener and more resilient buildings.

In conclusion, the evolution of WPC wall panels represents a remarkable milestone in the quest for sustainable and durable construction materials.

From their humble beginnings as a conceptualization to their current reality as a widely recognized building solution, WPC panels have transformed the way we approach wall cladding.

As the construction industry continues to prioritize environmental consciousness and seek innovative alternatives,

WPC wall panels are at the forefront, driving positive change and shaping the future of architecture and design.